Learn from our mistakes before you make yours!

I consider myself a pretty knowledgeable RC enthusiast/racer. I’ve raced at every level of competition, driven everything from 1/18-scale to 1/5-scale motorcycles and travelled all over just to play with toy cars. I’ve worked with NiCd, NiMH and LiPo batteries and been around every form of brushed and brushless motors. Even with this kind of resume, things still happen that can be considered a ‘newb’ move.

The Story

A couple months ago, I had a LiPo battery catch fire while working on one of my cars. I did everything right; used a high-end charger, had it set on the correct mode, positive lead to positive plug on the battery and had a balance board correctly connected. Even with all this, it still went up in flames and burned my race-ready Tamiya F104X1 into a pile of molten plastic. Thankfully I was able to get it out the back door before it burst (which it actually did as I was throwing it out…arm hair doesn’t smell very good), but this made me think about getting a real experts opinion and sharing with you my experience.

I contacted my good friend Ling. He worked in the product development department of a company that deals with medical devices. During his time there, he was in charge of developing a wallet sized device that was designed to vaporize liquid insulin. For those of you that don’t know, this type of device requires a ton of power in a tiny package. His research led him to the understanding of battery construction, failure analysis and audits of many battery manufacturers. To say that he has some knowledge of LiPo batteries is an understatement. After he heard about my LiPo woes, he contacted me and we had a chat. We decided that this was probably a good time to clear the air about LiPo batteries and this little interview is the result of that chat.

TONY: Ok Ling, what exactly is inside a LiPo battery? How similar is it to the older NiMH cells?

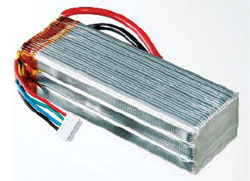

LING: A LiPo cell is a classic battery construction. It’s composed of an anode, a cathode and a separator. These components are inside the aluminum pouch and it’s filled with a liquid electrolyte. Oddly enough, the “Polymer” in modern Lithium Polymer cells refers to the electrolyte – which isn’t a solid polymer at all. The anodes are composed from a copper foil current collector coated with a fine particle graphite slurry. Most cathodes are composed of a LiCoO2 (lithium cobalt dioxide) coated onto an aluminum foil current collector. There are some other mixtures that they throw in there, but for the most part – it’s LiCoO2 based. The polymeric separator does just that, it physically and electrically separates the anodes and cathodes.

Surprisingly, RC LiPos are the exact same chemistry used in your cell phone or laptop. There is a tradeoff between Li-Ion cells: high energy vs. high power. Laptops and cell phones fall into the high energy category and RC LiPos fall under high power. The difference is really just the architecture of the cell.

The high energy type of cell generally uses a single anode/cathode pair with a separator between the two. This sandwich is generally rolled up in a “jellyroll” format to create either a cylindrical cell or a prismatic (rectangular) cell.

The high power type of cells are made of a multitude of anode cathode pairs. This is a stacked cell configuration. A typical LiPo is composed of 20-30 pairs of anode/cathodes. The separator is either a “Z” shaped accordion or a spiral wrapped between the anode/cathode. Think of an RC LiPo as a whole bunch of smaller cells where all the anodes are all welded together and all the cathodes are welded together. The actual thickness of a one Lithium Polymer cell (typically under 10mm thick) is actually limited by the number of anode/cathode pairs that are ultrasonically welded together. If there are too many parts of anode/cathodes, the ultrasonic weld will fail.

TONY: Good to know about the high energy vs. high power. Guess I won’t be hooking up a 6500mAh 65C rated battery to my iPhone. Speaking of that, what does the C rating mean?

LING: Technically, it means the relative charge and discharge capability. For simplicity, take the capacity in amp hours and multiply it by the C rating. So for a 5 amp hour battery, 1C = 5 amps, 2C = 10 amps etc. The discharge C rating is the maximum continuous discharge rating that a cell can handle. There are no industry standards which define when a cell fails a C rating, whether it’s the number of cycles, ending temperature, capacity, etc.

In the RC world, the C rating means next to nothing. I can pretty much guarantee you that just about every RC LiPo would self destruct when discharged at the C rating on the label unless it’s a short burst. For a 5000mAh battery, a 40C discharge is 200 amps. A complete discharge at 40C would last exactly 1.5 minutes There is absolutely no RC application that dumps the battery in just 1.5 minutes. A genuine Deans connector starts melting at 80 amps continuous – a fake Dean fails at even less.

TONY: Well, I always figured some of those numbers were a bit exaggerated. I’m assuming sticking to a quality, brand name battery is probably the best way to get an accurate C-rated pack. Other than that, is there any way to determine a quality pack vs. a cheap pack besides price?

LING: For the average consumer, it’s very hard if not impossible. High quality packs are distinguished by higher safety and abuse limits, higher cycle life, better cell to cell consistency, longer shelf life etc. Higher quality cells have higher standards for incoming material inspection, more in process inspection (high pot testing, X-ray detection of stack etc), and generally a much cleaner production line that limits the amount of impurities that can enter the cell. Once the cell is pouched, pretty much all cells look alike (high quality vs low quality) on the outside. The raw cost of a cell from a high quality manufacturer can cost about 4X more than a cell with the same specs from a low end manufacturer. Any high quality pack WILL cost more to produce, however, all expensive packs are not guaranteed to use high quality cells.

TONY: So, as far as LiPos go, it can be a ‘get-what-you-pay-for’ situation. Are there any benefits to hard cases vs. soft cases?

LING: Absolutely! Remember the copper anode and aluminum cathode layers I mentioned before? They are separated by a very thin polymer. A dent (especially along the edges) will cause the sharp edges of the copper and aluminum to damage and start eroding away the thin separator. This is exasperated by the naturally expansion/contraction of the battery during charge and discharge. Eventually, the eroded hole will lead to an internal short circuit. Best case, the cells short out internally and no longer hold a charge for an extended amount of time. Worst case, the short builds up temperature and leads to thermal runaway – ie. fire. So yes, absolutely, hard cases are beneficial.

TONY: Good to know…I’ll be placing all of my soft-case packs in a case! Hard-case packs from here on out! Let’s talk about charging them. Are there any basic charging guidelines?

LING: There is not much to it. Almost all chargers follow the standard CC/CV charge profile pretty well. With higher charge rates (like 2C and above), there is almost always a big drop in cycle life associated with it. The exception is Lithium Phosphate (LiFe), which does very well at higher charge rates, but those aren’t too common yet…

TONY: So stick with the standard charging guidelines as far as charging amps?

LING: For LiPos, I’d recommend charging 1.5C or under with a charger designed specifically for LiPos.

TONY: A question I’m sure everyone wants an answer to…is it necessary to balance a LiPo pack every time you charge it?

LING: This is a loaded question. For a high quality 2S pack (7.4V), it’s highly unlikely that the batteries will ever need balancing. For higher cell counts, 3S and above, it’s a good idea to balance charge. For cheap packs, it’s always a good idea to balance charge.

TONY: Well, for the sake of safety, is it a problem to balance LiPo packs regardless of their ‘supposed’ quality?

LING: Balancing is an insurance policy. It prevents a cell from getting overcharged. Overcharging is a surefire way to get a LiPo cell to erupt into flames. Unlike NiMH or Ni-Cd, Lithium Polymer batteries cannot tolerate or absorb any overcharge.

TONY: What does it mean when the battery pack looks puffy or bloated?

LING: It just means that the electrolyte has started to break down. A lot of things can cause this: over-charge, over-discharge, over-heating, cell contaminants, internal corrosion, poor material purity, etc. It takes very little liquid to form a whole lot a gas. Unfortunately, puffing is very bad. The anode/cathode layers are vacuum sealed in an aluminum pouch. This vacuum seal helps prevent the anodes/cathodes from shifting around and shorting out on each other. Once puffy, the vacuum is gone and the cell is much more likely to internally short out and, as mentioned before, an internal short may lead to fires.

TONY: So, let’s say I’m going to take a short RC break. Are there any good storage tips?

LING: Shelf life is largely determined by temperature. A rule of thumb is with every 10 degrees, the C is double the degradation rate, so keeping the cells in a cool spot is the good idea. Also the cells like to be partially charged – usually between 20-80% of full. A fully charged cell stresses the internal chemistry and degrades the cell much faster. Think of it as compressing an overstressed spring – if you hold the spring momentarily, it pops back in shape. If you hold it down for a long time – it tends to take a set.

TONY: So a springy LiPo cell is a bad thing. Check. Well, I actually have a few puffy cells here that I’ve been hanging on to for, ummm, whatever reason. What is the correct procedure for destroying a LiPo pack?

LING: I’ve read about the salt water type disposals. The salt conducts and drains the battery; the water is there in case there is a fire. That will work just fine, but I think it’s cumbersome and overkill. Personally, I just discharge the cell at a low amperage rate, usually as low as I can get it. You can run it in your RC car, but I would turn off the low voltage cutoff. You definitely want to go well below the LiPo cutoff. A drained battery has no stored energy. A cell with no stored energy cannot ignite.

TONY: I’m assuming you’ll want to run it at a slow speed so as not to stress it out? I’d hate to have ANOTHER car catch on fire as I do this.

LING: If you have a discharger, I’d use that and a LiPo sack. This way you don’t have to risk a RC vehicle. A discharger can easily take down the energy in a LiPo. If you don’t have a discharger, you can run it at low speeds to bleed off the stored energy, though there is still a little bit of risk.

TONY: Ok, well, that should just about do it. Thanks Ling, I appreciate your time in helping with this article.

LING: No problem buddy, I’m here to help. Just let me win the next time we race – OK?

TONY: You got it!

WRAP-UP

As you can see, there’s quite a bit going on with LiPos but, if used correctly, they are just like any other cell. I’m sure there are a TON of other questions that could be asked so, in the name of safety, I will be answering any additional questions you might have about LiPo battery safety on this web site.

Large selection of LiPo Battery Charging Bags.

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.

When I read that I wonder why NIMHs have become so unpopular. NIMH batteries can store a lot of juice and are much safer as I understand. I just saw one on sale online with a capacity of 4700 mAh. So why give up on the safety of NIMHs for LIPOs?

Good article by the way. Thank you very much for this.

LiPo has taken over simply because they provide a ton more power and are much lighter than NiMh cells. They’re also very close in price. Kinda like buying a Ferrari for the cost of a Honda.

Thanks for the kind words. It was a fun article to research.