Beginner’s Guide to RC – Does Changing a Brushless Motor Rotor Really Make a Difference?

Before brushless motors were around, there was quite a bit of maintenance we had to perform on our motors to keep them fresh and running strong. Our pits would be filled with a comm cutter, comm cleaning sticks, a variety of brush compounds and loads of springs bent with different tensions. On top of that, there was a secret combination of all of those that would extract the super duper power we’d need to win a race. Racing was not just about driving, but about motor maintenance as well.

Then came the brushless motor. Yes, I know some of you are wondering how RC even existed before brushless (I wonder the same sometimes), but this technology changed the entire racing scene. One question I get a lot is if there are any go-fast tips a general user can do to their motor to gain an advantage. The answer is yes, but unfortunately (or fortunately, depending on how you look at it) it’s one tuning factor that isn’t very well known.

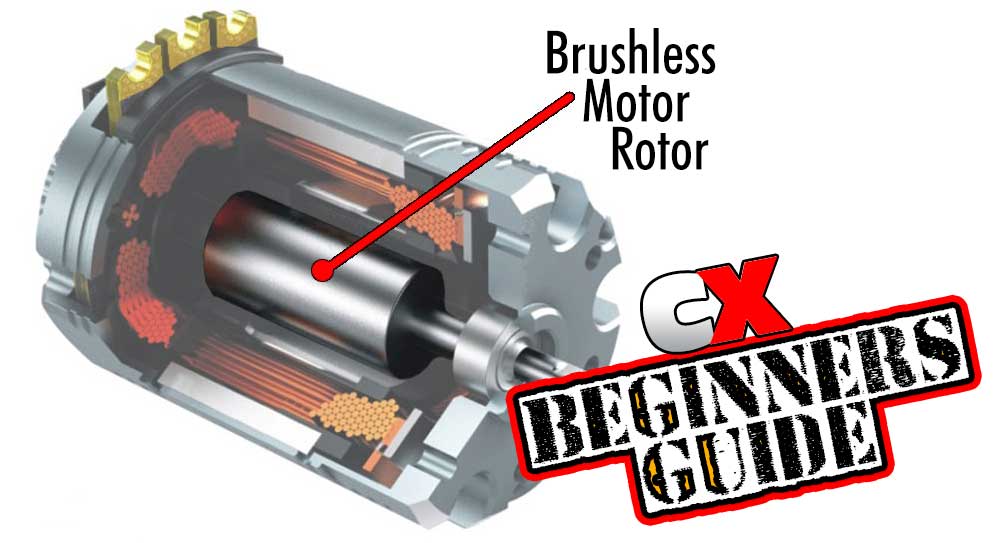

We’re talking about the internal rotor – basically a round magnet attached to the motor shaft. Changing this rotor can actually change the way your motor runs and, while I know enough about rotors to give you an idea of what the changes will do, I thought that an explanation from one of the leading brushless motor manufacturers would probably be best…you know, since they kind of have a bit of data to back up their words.

A while back I spoke with LRP’s very own Reto König about this very thing. At the time, Reto was LRP’s Project Manager and has been an instrumental part in quite a bit of LRP’s product line. We talked, I took notes and this is the rundown on changing out a rotor in your brushless motor.

Rotor types:

Rotor types:

Usually the rotor, which is supplied as standard with modern brushless motors, is a pretty good compromise and “universal fit” for most classes. Nevertheless some further performance can be achieved by fine tuning the motors characteristic using optional rotors with different sizes or properties.

Rules of thumb:

1) Lighter cars (1/12, WGT) require “weaker” magnets than heavier cars (TC, 4WD). These types of cars benefit from higher RPMS, thus the weaker magnets.

2) Lower battery voltage (1S LiPo) requires a “weaker” magnet.

3) When changing the rotor, the speed-controls drag brake and gearing needs to be adjusted.

weaker magnet = more drag brake + lower gear ratio

weaker magnet = more drag brake + lower gear ratio

stronger magnet = less drag brake + bigger gear ratio

stronger magnet = less drag brake + bigger gear ratio

Changing the rotors characteristics (“weak vs. strong”) can be achieved in different ways. These are:

1) Change rotor outer diameter (for example, 12.0mm is weaker than 12.5mm)

2) Change rotor inner diameter (for example, a bigger hole makes a weaker magnet than a smaller hole)

3) Different magnet grade but having same size of magnet.

4) Change the shaft material.

All these can affect the magnetic characteristics of the motor. Most manufacturers typically offer rotors with different outer diameters, meaning options 2) to 4) can be disregarded in most cases.

| Magnet Type |

Weak (e.g. 12.0mm) |

Medium (e.g. 12.5mm) |

Strong (e.g. 13.0mm) |

| RPM | + | O | – |

| Torque | – | O | + |

| Efficiency 2S | O | O | + |

| Efficiency 1S | + | O | – |

| Temperature | O | O | + |

| Natural Drag Brake | – | O | + |

Motor Timing:

Motor Timing:

There is no “good” or “bad” motor timing. Motor timing needs to match the speed-control settings and gear ratio. Unfortunately there is no industry standard for motor timing so manufacturers refer to “zero” at different points. Most manufacturers refer to 30° as the “zero timing” normally because anything lower can cause poor performance.

| Motor Timing | Low (e.g. 20°) |

Medium (e.g. 30°) |

High (e.g. 40°) |

| RPM | – | O | + |

| Torque | High | + | Low |

| Temperature | Cold | Standard | Hot |

| Gear Ratio | Higher | Standard | Lower |

| ESC Timing | High | Medium | Low |

Speed Control Settings:

There are many different speed controls nowadays and all of them have their pros and cons. Some are easier to adjust with preset profiles while others are almost “open platforms” where you can adjust every little detail.

Therefore, I will keep the speed control advise very simple:

ALWAYS read the manufacturers user manual. Follow their advice for correct settings for each motor and also the motor’s thermal limit.

ALWAYS read the manufacturers user manual. Follow their advice for correct settings for each motor and also the motor’s thermal limit.

Different motors may need very different settings. Always start with mild speed control timing settings and monitor the motor temperatures during the run when making changes.

Different motors may need very different settings. Always start with mild speed control timing settings and monitor the motor temperatures during the run when making changes.

Higher speed control timing will increase power to a certain point where it may drop again, but also increase motor temperature.

As you can see, swapping out the rotor in your brushless motor is an easy way to modify its performance. Following the above rules help to make sure you keep it running it tip-top shape. I would also check with your track to make sure they don’t have rules regarding brushless motor rotor modifications.

Thanks to Reto and LRP for helping us with this article.

Here’s another cool article on brushless motors you might like: Brushless Motor Chart – Turns vs kV Rating

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.