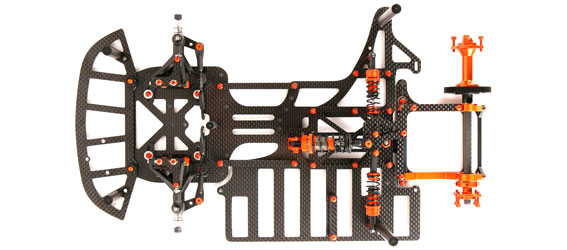

Last year, across the country, many oval pan car racers have been struggling with too much weight transfer to the right front, picking up the left wheels, or even traction rolling. This happened when the rules changed from 41 oz to 36 oz to accommodate the lightweight single cell LiPo battery. We went from the heavy NiMH 4-cell packs and 2-cell LiPos down to a single cell LiPo. No longer having the heavy packs keeping the left side of the car down, racers discovered these handling problems with most pan cars. When running a mere 36 oz, we lost a considerable amount of left side (and forward) weight percentage. This new Dart 2.5 was designed specifically to address these problems. This new 2.5 car will run flatter and turn harder. It provides more left side grip than ever before.

• The Dart 2.5 offers an offset T-plate and now a super offset T-plate position. We removed the centerline T-plate position. This also moves some weight to the left even more (all 3 shocks, center shock mount, T-plate, float bridge, supporting hardware, etc.)

• We shortened the wheelbase a lot with the Dart 2.5!. You can slide the wheelbase anywhere from 9.75″ – 10.06″ (as opposed to 10.03″ -10.32″ with the 2.0). A short wheelbase allows the car to turn hard. (Imagine how poorly a dragster would turn on an oval track.) Traditionally, a short wheelbase can make a car too squirrelly, but we were able to get away with this for a couple of reasons. First, we took advantage of the Dart’s notoriously excellent rear grip. The Dart’s ultra low rear roll produces more rear grip than other pan cars as it keeps more weight on the left rear in the corners. (On the scales pan cars can look similar, but if you could weigh the LR in the corner, you’d see there is more weight due to the physics of a low rear roll center.) Secondly, the front locator track width adjustments lets you fine tune how much weight gets transferred making handling changes easy. When the car is handling right, you can get away with a short wheelbase and take advantage of it’s turning capabilities.

• We shortened the “neck” of the chassis so that the carbon fiber flex braces are now the same size (2.55″) as the clamp links (CRC or Associated) giving you lots of possibilities.

• We added new rubber o-rings designed to work with the carbon fiber flex braces which eliminates all tweaking.

• Both motor pod plates were lightened some more.

• The left motor pod plate was designed to get easier access to the T-plate nut.

• The LiPo strap brace was moved to the rear of the battery allowing the battery to move toward the LF wheel. This increased front weight percentage.

• The left side of the chassis was moved out .100″ to increase the left weight percentage and also taking advantage of the newest Protoform D-HD nationwide body.

• We added new standoffs to flatten the angle of the side shocks. In our testing, this has proven to be better.

• We added an extra front hole in front of the battery and filled in the carbon fiber near that area giving you lot’s of options to use small carbon fiber braces (shown in more detail below)

Lowered Center of Gravity

As you can see, we lowered the side shocks nicely with low mounting underneath the top plate. The shock travel still has a perfect range of motion. This design totally eliminates the need for a crossbrace and supporting hardware which saves even more weight. If you are still running 2 cell LiPo or want use the old crossbrace for some other reason, it’s no problem. This new chassis is backwards campatible with the Dart 1.0 crossbrace and upper pod plate.

To lower the center of gravity even more, we lowered the entire floating T-Plate bridge and shortend the standoffs.

Lightweight Center Shock Mount

We designed a new aluminum center shock mount which is 63% lighter than the traditional center shock mount. The new center shock mount weighs only 0.10oz. We’ve also included a new Dubro ball link and cone washer for your center shock. This removes the slop. It’s not as important for side shocks, because they have constant pressure against each other. But for the center shock, there is a point where it transitions from push to pull. The Dubro and cone washer solve this problem.

We are sticking with HPI’s newest center shock. It was the lightest and also had the least amount of piston slop compared to the others. The e-clips hold the piston securely. The latest version has a few new design improvements. Instead of a double O-ring seal, they now use a single O-ring in combination with a plastic retainer. This helps to reduce the friction on the shaft while retaining a superb seal. Those components are now encased by a new housing that makes it easy to assemble or perform maintenance. The shock cap has also been redesigned with edges to provide a better grip. The shock still used the bladder for the ultimate in consistency. The shock is made out of 7075 aircraft aluminum.

Complete Flex Control

This car was designed so you could have complete flex control for any classes, types of tracks, track conditions, or battery type. If you prefer a lot of flex, there is no need to cut your chassis with a Dremel. On the other end of the spectrum, the new design also allows you to build a rock solid chassis. They can be used in various combinations or doubled up to get the desired effect. You’ll be able to control both the twist and the bow (belly of the chassis sagging down or arching up). There are literally millions of possible combinations with the braces provided in the kit, but don’t worry, it’s actually pretty easy to understand and document on setup sheets.

Rule of thumb for flex control

• The plastic clamp links provide the most flexible setup overall. They provide impact strength without adding any twist or bow/arch resistance.

• Carbon fiber braces aligned parallel (front to back) will increase the bow/arch strength, but not add much twist resistance.

• Carbon fiber braces angled towards the center in a “V” pattern will significantly add a lot of twist resistance, but not add much bow/arch resistance.

• The higher the carbon fiber brace is off of the chassis (using spacers or standoffs), the more effect it will have.

Use the provided collection of ball studs w/ clamp links, carbon fiber flex braces, flathead screws, locknuts, spacers and washers to design the car for your situation. Be creative. You can bolt the carbon fiber flex braces right down to the chassis, or you can double them up, or raise them up with spacers and standoffs. You can use more than two braces as well. You can also run one set parallel, and one set angled. They do not have to be symmetrical nor do you need to add them in pairs. You could run two on one side and one on the other for example. Just make sure you have at least one brace or clamp link on each side of the chassis for impact resistance. Your kit comes with these items to allow you to design your own flex.

Slower classes or wide oval tracks:

Generally, a very flexible chassis is usually desirable these situations. With less G forces, there is less weight transfer to the RF. A flexy chassis encourages more weight to transfer which can give you that quick snap you are looking for when the car first dives into the corner. Secondly, a flexy chassis acts like a very consistent suspension, which is usually better than springs and kingpins.

Faster classes or paperclip tracks:

These usually require a more rigid chassis as a lot of weight transfers to the RF which can cause it to bite too hard, providing so much traction that it might traction roll or spin out. A stiffer chassis will keep more weight on the left side in the corners.

Fully Adustable Front End Wheelbase and Track Width

New locators allow each wheel .267″ front to back, and a whopping .400″ side to side! The same ride height spacers that you are accustomed to using won’t change either. To compensate for the thickness of the carbon fiber locator (.100″), we machined the same amount off of the lower arms. The wheelbase and track width are infinitely variable.

Advantages of our front end:

• Much faster to make changes. No need to install spacers to change your track width. Simply loosen 3 screws, slide to desired location, re-tighten.

• Faster alignment after changes. Does not require readjusting your camber after making track width adjustments like the R5 or Black Mamba front end.

• Infinitely variable track width adjustments. Does not rely on the use of spacers or limited slug locations.

• Infinitely variable wheelbase adjustments. Front to back adjustments only require loosening 2 screws. You are not limited to a series of holes. For example, if you want to lead the left front by just a hair, it’s easy to do.

• Lighter. Our Dart 2.0 Standard front end is 28.2% lighter than R5 and 21.7% lighter than Black Mamba. The Dart 2.0 Team Kit front end is 33% lighter than R5 and 26.3% lighter than Black Mamba.

• Does not increase in weight since it does not require spacers to adjust the track width.

• Greater range of adjustments. This can help to counteract the loss of left side weight percentage when running single cell LiPo.

• Designed to accommodate either a standard mounted servo or forward mounted servo (see next section).

Forward or Rearward Mounted Servo

We redesigned the front end to accommodate your choice of servo position. With single cell racing, we lost both left weight percentage and front weight percentage. Using the forward mounting position is beneficial for two reasons. It increases the forward weight percentage which has proven to be desirable in single cell racing. Secondly, it moves weight more towards the suspension mounting points which keeps the chassis settled/flatter over bumps. If your servo does not have the ears intact, you can recreate them with thick Lexan bent into a 90 angle and epoxied to the servo.

You’ll notice that the rearward mounted servo still accomodates the flex control braces even in their most aggressively stiff crossed over position.

Flat Servo Mounting

There is a way to mount a servo flat while maintaining the perfect Ackerman and bumpsteer. Although you can drill your own servo holes for any servo (running flat or angled), we recommend the Futaba 9650, 9602, or BLS651. The chassis comes pre-drilled to run the 9650, 9602, or BLS651 servos flat. With the correct Ackerman, zero bumpsteer, and running flat, you reduce your center of gravity big time with this set up. Additionally, the 9650, 9602, or BLS651 servos come with side mounting ears. This reduces the weight because we can eliminate the servo mounts completely as the servo bolts directly to the chassis! Have a look at the picture and you’ll see it doesn’t get any more efficient than that. We’ve included 4 Dubro ball links that help us to remove the bumpsteer. Just as importantly, there is less steering slop with Dubros when comparing to the traditional ball cups and ball studs. The techniques to remove slop from the traditional ball cups and ball studs can work, but at the expense of adding resistance. Dubros have less resistance and allow the servo to work easier and center correctly. We’ve even included shorter 1.25” turnbuckles to match the Dubro links perfectly, along with a cone washer (needed for the right side), and 2-56 locknuts. If you desire to run an angled servo, angled servo mounts and longer turnbuckles are also included in the kit.

T-plate vs Mono-ball

We stayed with the proven T-plate design instead of following the recent mono-ball trend. Only a T-plate (and not a T-plate with 4 pivot balls on it) can encourage the car to quickly settle back into its natural ride height position by providing smooth progressive resistance in both directions. See our diagram for further explanation.

Adjustable Spring Steel T-Plate

The Team Kit comes with an adjustable spring steel T-plate! Slide the adjustment screws towards the rear of the car to make the T-plate stiff, or slide it forward to make it soft. This new spring steel T-plate only requires one tool, as the nut has been machined to fit in the slot. This means, you can put your hex driver in your back pocket when you go out for practice. Flip the car upside down, make an adjustment to the T-plate, set it right back down. No need to go back to the pits.

Also notice the easy access to the side springs. The new design makes it very easy to get your fingers on the spring collar.

Delrin Body Posts

16 body post locations! We also didn’t give you the cheap flimsy body clip style posts, we gave you machined Delrin body posts. The bottom of the post has been machined perfectly flat and a hole directly in the center. A hole exactly in the center means it’s easy to change the posts or exchange bodies since it lines up in the same spot every time. While there is some adjustable body posts out there, these usually are aluminum or partly aluminum. The aluminum adds unnecessary weight. Compared to the aluminum/Delrin posts, posts made entirely of Delrin cut to the right height (we will show you how) are lighter and lowers the center of gravity.

You’ll also notice that the center post gives you three center mounting choices more rearward. Having it moved rearward provides stronger mounting method due to the triangle effect of the front 3 posts. This allows the body shape to have less vibration and remain more solid when traveling over bumps or when receiving aerodynamic down force.

We also moved the rear body posts back further to allow for more body stability, less wing flutter, and ease of shock adjustment. Shocks easily clear the posts, and no problems getting your fingers on these shock collars!

Offset / Super Offset T-Plate and Pod Position

Not only do we have a floating T-plate design, but it’s also adjustable. You can run the T-plate and pod in the offset or super offset position. (We removed the centerline T-plate position.) This also moves some weight to the left even more (all 3 shocks, center shock mount, T-plate, float bridge, supporting hardware, etc.) The lower pod plate has all 3 sets of holes. This allows you to use the same symmetrical T-plate in all 4 options. Here are the 4 possible options.

Aluminum Screws, Locknuts, and Cone Washers

As you can see by the pictures, the Team Kit comes with aluminum anodized screws and locknuts. About 95% of the screws and locknuts are aluminum. Not only do they look good, but they also reduce the weight, so you can add weight where you want it. The aluminum screws save a full ounce of weight! Compared side by side to the Standard Kit, the Team Kit can run 2 more additional short pieces of tungsten, or 1 + 1/5 long pieces.

Due to their size, the two brass cone washers are still needed for the left caster block, but the Team Kit also replaces the other two brass cone washers with aluminum cone washers. This will save you a little more weight. They are seen on the center shock and right steering block. We’ve also include two 8-32 locknuts. These can be used for the bumper, but might be better used for the diff nut. They provide very flat pressure on the diff.

Carbon Fiber

All of the chassis components are made of 2.5mm quasi-isotropic carbon fiber. Cheaper carbon fiber is created with layers aligned in only two directions: 0 degrees and 90 degrees. We use quasi-isotropic carbon fiber, which means the layers are 0 degrees, 90 degrees and 45 degrees. This allows the strength to be higher and even in all directions. This allowed us to design it lighter with less material, and the flex will be consistent from kit to kit.

Bumper

Working our way front to back, we designed a bumper that allows you to mount the transponder flush with the bottom of the bumper or chassis. This lowers the center of gravity. The leading competitor’s bumper uses a thin 0.84” carbon fiber material. We chose to stay with the full strength 0.97” carbon fiber material and yet our bumper still weighs less. Three body mount holes gives you choices on where you want to mount your Delrin body posts. A new COT bumper is also available in our web store.

Kingpin Upgrade

The stock kingpins are so short that the e-clips ride inside the upper eyelets and cause the front suspension to bind. So, we have included many improvements in the kit. You’ll be receiving long WindTunnel 1.5” kingpins, WindTunnel black front springs, and 4 spring buckets. Much better! You can still use the small Associated front springs if you wish. The blue spring buckets allow for the large or small springs without needing to change the spacers.

Boca Bearings

We wouldn’t give you some mystery no-name bearings either. You will be receiving Boca Bearings throughout the entire kit.

Caster Blocks

The Team Kit comes with two 10 degree reactive caster blocks. “Reactive caster” is sometimes called active or dynamic caster. It provides dynamically changing kingpin angles depending on how much the suspension is compressed. Reactive caster is controlled by the angle of the caster blocks. The more angle, the more the kingpin will stand upright when the suspension is compressed. With reactive caster, you’ll have more positive caster in the straights and less in the turns. Positive caster tends to straighten the wheel when the vehicle is traveling forward which enhances straight-line stability. Bottom line is, your car will be just as aggressive in the corners, but easier to drive in the straights. We’ve done a lot of testing with the different blocks, and found that the lap times increased and were most consistent when running two 10 degree blocks. You should note that a 10 degree caster block does not give you 10 degrees of caster, it gives you 10 degrees of “action” so to speak. Spacers are used to set the initial amount of caster, and the reactive caster block changes the kingpin angle under compression.

Our aluminum caster block are designed light with a slightly lower center of gravity, and we included a little more threads than normal so you won’t have to worry about your 2-56 screw stripping out. The rear upright allows a long 2-56 screw do reach all the way down and hold the hingepin. The spacers seen in front of the caster block are optional for added peace of mind.

Bump Stops

The Team Kit comes with bumpstops and self-locking hingepins as well. Bumpstops can be used for two things:

1. They can be engaged slightly, just enough to prevent the chassis from bottoming out. This alone is worth having bumpstops. When you get black on the bottom of your chassis, you are scrubbing speed, either through the added forward resistance, or loss of side bite.

2. Bumpstops can be engaged harder to be used as an added tuning aid. You can use them to help individually control the specific point in the corners where each tire is pressing hardest on the ground. They can also help control chassis roll, but should not be used as a crutch for a poorly set up car. (ride height, wedge, weight distribution, side shocks, tire compounds, RF springs, among other things are all factors in chassis roll)

LiPo Mounting System

If you plan on running LiPo’s, you may be pleasantly surprised at our LiPo strap retaining method. Although you can use tape, we wanted to offer a retaining system that uses a screw down method for the convenience factor. The competition uses 4 standoffs with 2 braces. The downfall to this method is the standoffs move your LiPo battery inward towards the center of the car. We came up with a method that holds the LiPo all the way out to the very edge of the car for maximum left side weight. We also did it with half of the standoffs, braces and screws. Additionally, the two standoffs are lighter since they are shorter, and the single LiPo strap brace is positioned lower than the top of the battery for a lower center of gravity. With only two screws, simply screw down the LiPo strap into the standoffs. This pulls tension on the retaining strap keeping everything solid. The chassis allows you to run the single cell battery all the way forward, or one set of holes towards the rear.

The tape you see in the picture is not sticky. It’s been doubled over so there is no stickiness exposed. It’s being used as a retaining strap only. Since the sticky side is not being used, it’s reusable too.

Side Shocks

Your Team Kit has upgraded side shocks as well. It comes with Silva HPS2 side shocks. These are a bladder shock, easy to build and are extremely smooth. The spring does not rub on the shock body or spring retainer. The side shock angle can be adjusted for a more linear or progressive feel using 3 different ball stud heights (medium and long ball studs are available separately).

Floating T-plate

A floating T-plate design allows the pivot ball to be lower which reduces the rear roll center. Our new pivot ball and pivot ball socket design has a much lower rear roll center than anything available. It’s also has the largest range of rear roll center adjustability. Dart 2.0 now comes with heavy duty pivot balls.

Low Rear Roll Center

So why is a low rear roll center so important? What are the benefits of a really low rear roll center? For starters, it allows the rear pod to roll easier, in both directions. This makes for a more efficient rear suspension. Your side shocks, oil, and springs will receive more activity and be more effective because there is less pivot resistance (not referring to friction) in the rear suspension. The second major benefit of an ultra low rear roll center is more left weight in the corners. You can scale a standard T-bar car and a floating T-bar car and have identical 15.5 oz on the left rear tire. It would seem like they would have the same weight on the left rear in the corner. But the car with the lowest rear roll center will keep more weight on the left rear in the corner. On the other hand, a high roll center will not allow the chassis and rear pod to roll independently as easily, therefore the entire car rolls when it goes into the corner. Weight comes off of the left rear tire. That’s bad! So low roll center fixes that.

Lowest Rear Roll Center

A standard T-plate car’s rear roll center is 0.1435” from the top of the chassis. Our pivot balls and pivot ball sockets provide the lowest rear roll center available. Click here for a video of how our pivot ball sockets are machined. It’s important to note that the T-plate height does not determine the roll center, the pivot ball does. It’s hard to tell from the above picture, but our pivot ball is actually flush with the bottom of the chassis! Viewing the diagram below, you can see how low our roll center is.

The end result? More rear grip. And more importantly, a much better version of rear grip! Since the left rear tire is now providing more traction in the corners, you now have more stability and consistency. As a bonus, the left and right rear tires will wear more evenly. So what will you do with all of this new rear grip? There are many options, but the most dramatic would be: you can reduce your rear spoiler or wing down force for more speed. You could also go to an exotic rubber family of tires which produce less grip, but are lighter with less rotational mass. Or keep it all and you’ll be able to safely add more front grip (which is much easier to do). Your car will turn like it’s on rails!

Nerf Wing

You’re probably thinking, “What could you possibly do to a nerf wing to make it worth mentioning?” Well, do you ever get black stuff under the bottom right side of the chassis? Nerf wings don’t usually rub on the ground since they sit higher than the chassis. So we extended the nerf wing longer than average, so that we could make the chassis narrower on the right side. This gives us two benefits. First, it allows for a little more side to side motion with less chassis rub. Secondly, it saves weight having a narrower chassis. We added two new body post mounting options to the Dart 2.0 nerf wing.

Topless Motor Pod Design

There was nothing available on the market that could do everything we wanted, so a fresh design of the entire pod was the proper solution. This is what put us over the edge from simply making a conversion kit, to a whole car. A completely open top plate design allows for easy motor swapping. No more need to take your pod apart in order to get the motor out! No problem using any type of motor heat sink either. There’s plenty of room. We have many requests NOT to change the motor pod for the Dart 2.0, and of course, we left it alone.

Lowest Center of Gravity

A front pod brace and rear dogbone brace makes the entire pod rock solid. Essentially, we moved the top plate material down to the front and back of the pod. This lowers the center of gravity. To help further, the small remaining top plate was also lowered more than everything else available. This allows the center shock to be even lower as well. Speaking of lowering the center of gravity, we made sure the motor sits perfectly flush with bottom of the chassis. It’s surprising how many cars kits don’t do this.

Easier Brushless Wiring

The motor mounting was positioned so that the solder tabs are straight up and down. This makes the wiring easier and keeps them away from the tire and body post.

Roomiest Motor Pod

One of the biggest improvements was the amount of room for motor movement. This pod gives you more room than any competitor (and we didn’t extend the wheelbase to do it). You can fit a 65T pinion with a 124T spur gear with some room to spare! Bigger pinions and spurs allow for a more efficient gear mesh. Brushless motors really seem to benefit from this. Another benefit of moving the motor forward is it reduces the pendulum effect. Having too much rear weight near the rear axle can cause the rear end to keep swinging outward in the corners. Moving the motor forward helps to reduce this effect.

Did you ever think you could fit a Novak heatsink lying down? Removing the inner “V” from the heat sink would provide even more room.

Rear Steer Bottom Pod Plates

Rear steer slugs with panhead screws require that you raise your ride height up in order to pass tech inspection. Since slugs are usually made from aluminum, they add a little weight as well. The optimal solution is to offer various rear steer pod plates with countersunk flathead screws. However, it’s not a good design to have these countersunk holes right near the edge of the carbon fiber. This is a weak spot in the design. So we designed a way to position the screws so that the countersinking never comes close to the edge of the carbon fiber.

The kit comes with a typical 0.0 degree plate, but 0.5 degree and 1.0 degree rear steer plates are available.

Left-Most Pod and Motor

Unless you are running large Veledrome sized tracks, you’ll find that getting your weight to the left as much as possible will help many things like improved left side tire wear, increased traction, reduces excessive roll, etc. In most cases, offset pod is today’s choice for most racers. So we improved two things. First, we moved the entire pod to the left as much as possible. Secondly, we moved the motor (within the pod) as far as possible. In the picture below, notice how far left the motor is. The pod and motor are more to the left than anything available.

Lightweight, Left weight, and Low Center of Gravity

You may have noticed a theme throughout the design. We’ve designed everything lightweight, we moved the weight to the left, and we moved it low. There are some racers who don’t think the location of weight matters much. They don’t care if their car is heavy throughout since they have to make weight anyway. I often give them the analogy, “If you don’t care where your weight is, then put a rigid fiberglass rollover antenna on your car with your lead weights at the top. I’ll put my weight low and left. Now let’s race and see who can turn better.”

Tungsten

Having a lightweight car throughout allows us to use more weight where we want it. So we designed the car from the beginning to use the ultimate weight, tungsten. The word tungsten means “a substance of high density”, and is derived from the Swedish language, “tung” (meaning “heavy”) and “sten” (meaning “stone”). It’s an appropriate name as tungsten is a metal with one of the highest densities. Tungsten weighs 1.7 times more than lead! Only gold, platinum, and a few other precious metals have a similar density. Tungsten is also completely non-toxic and environmentally friendly. It’s a really hard metal, and will last for years. It’s a nice one time investment.

It does not look like it, but the 7 tungsten plates in these pictures weigh a whopping 4.77oz! You can see that we designed the plates to fit exactly into our chassis. No more need to put lead on top of the chassis or components. Since LiPo’s take up most of the left side, most racers have been placing their lead inboard towards the center. With our new chassis, the tungsten plates fit UNDER the batteries and electronics! It’s flush with the bottom of the chassis. You can’t get weight any lower and more left than this. Not only does this lower the center of gravity, but the plates are also used to lock the LiPo battery in position. The LiPo can’t move at all with these plates servo taped to it. These tungsten plates are expensive, therefore they don’t come in the kit, but they are available separately.

The new Dart 2.0 has been designed to allow for the long tungsten pieces up front compared to the Dart version 1.0. This increase front weight percentage which is desirable in single cell racing.

[source: www.mcpappyracing.com]

[source: www.mcpappyracing.com]

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.