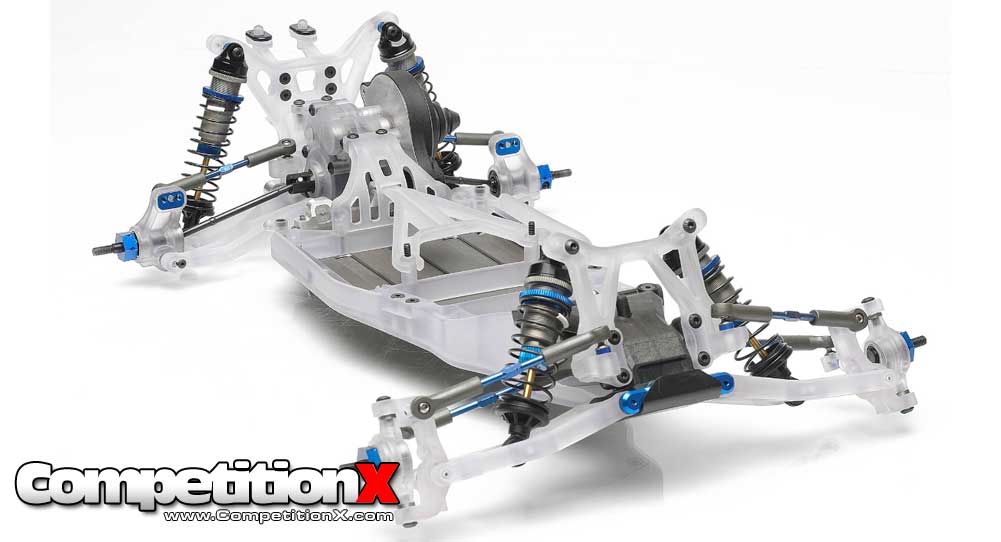

Team Associated posted a few rare pix on their Facebook page of their newest mid-motor buggy, the B5M. These aren’t just any pix, however, these are pre-production shots of the buggy in SLA (or rapid-prototyping) form.

This procedure is similar to 3D printing. You create the part in a program like SolidWorks and then basically print it out. Companies use this procedure to test fit parts to make sure everything lines up correctly, there is no interference with other parts and to help them make any changes before the product goes into production.

Before rapid-prototyping, companies would design, send the file over to have a mold made (in this case, a mold for plastic parts), test the mold by injecting it with plastic and then getting the sample parts shipped back to them. They would then measure, test fit and correct any issues to the file, send it back and have the mold modified. You can see how long this could take, not to mention to mention the money involved in making and modifying molds.

We’d like to thank Team Associated for putting these pix out there for everyone to see. I’d sure like to have a clear B5M … hint hint.

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.