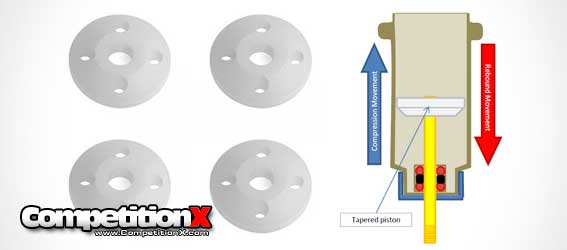

New Factory Team machined pistons for the 12mm big bore shocks take performance to the next level. Precision CNC machined pistons allow for the best fitment and concentricity with the shock body to improve handling and consistency. The new pistons are also tapered for independent tuning of compression and rebound.

Terminology

• Compression movement: Shock piston traveling upward toward the top of the shock

Rebound movement: Shock piston traveling downward toward the bottom of the shock

• Tapered piston: One side of the piston face is flat; the other is tapered / angled

Flat piston: Top and bottom of the piston face are flat

Difference between tapered and flat pistons

• A flat piston will travel at the same speed in compression as it does in rebound (given equal force is provided in both directions)

• A tapered piston will travel faster in the direction of the taper/angle.

For example, a tapered piston with the taper facing down will travel faster in rebound than it will in compression, allowing the user to tune the rebound and compression movement independently.

Piston Hole Size

• Larger holes allow more fluid to pass through the shock piston, which allows the shock to move faster.

• Smaller holes will have the opposite effect, causing the shock to move slower.

Piston Hole Count

By changing the number of holes in the piston, a similar damping level can be achieved with different amounts of “pack.” Pack is the feeling of hydraulic lock in a shock when the fluid flowing through the holes reaches a certain speed. It can be used to keep a car from bottoming out during harsh landings.

[source: www.rc10.com]

[source: www.rc10.com]

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.