In Part 2 of this Series, ROCHobby assembled the body of the Type82E Kommandeurwagen – that included the glass, doors and lighting. In this final post, we show you the how they combine the chassis and body set into a fully operational 1/12 scale ride! They also touch on the quality control and testing of the vehicle before boxing it up for shipping!

Part 1: ROCHobby Type82E Build Process – Part 1

Part 2: ROCHobby Type82E Build Process – Part 2

Part 3: ROCHobby Type82E Build Process – Part 3

Ok, let’s get to it!

Founded in 1937, Volkswagen’s first product for the civilian market was the heirloom classic, the Beetle, then known as the KDF Wagen, which was widely used during World War II and shared the same chassis as the famous military jeep Type 82 Kubelwagen barrel car. For more information about the Type82 Kubelwagen,please refer to https://www.youtube.com/watch?v=_mHQw2yjx1o&t=67s.

Today let’s take a visit at FMS factory to see how this Type82E/87 Military Beetle is produced.

Since its release, the ROCHobby 1/12 Kubelwagen has received great reviews from users all over the world, not only from a large number of modelers but also from industry media, reviewers, real car collectors, military experts and more. We are glad that people like this kind of dynamic model, and we will continue to bring you a richer line of 12th scale products that can carry figures.

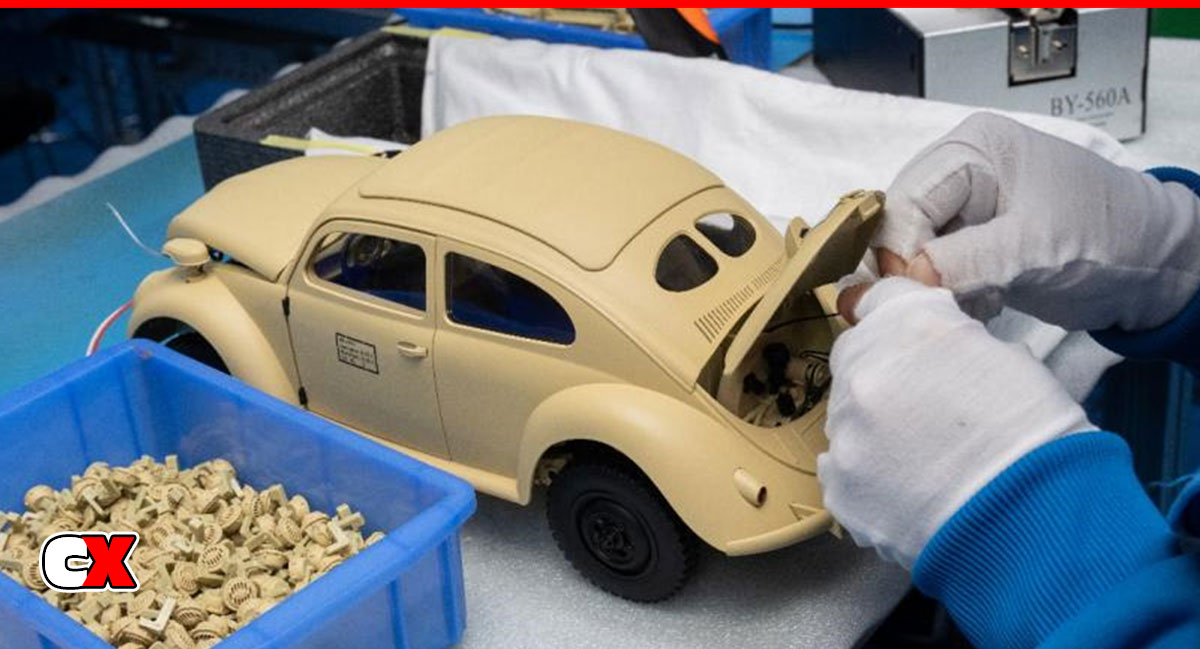

After a long assembly line and dozens of stations, we are in the final assembly process. Because the chassis and body have electronic equipment, there are many wiring harnesses that need to be carefully assembled.

Attaching the chassis screws in place after assembly.

To prevent damage, the almost-completed Beetle sits in a special jig when the workers attach the bumper. The front two screws also lock the chassis in place. In case of a collision, the bumper can be easily removed and replaced by the end user.

Attaching the lighting at the rear of the car.

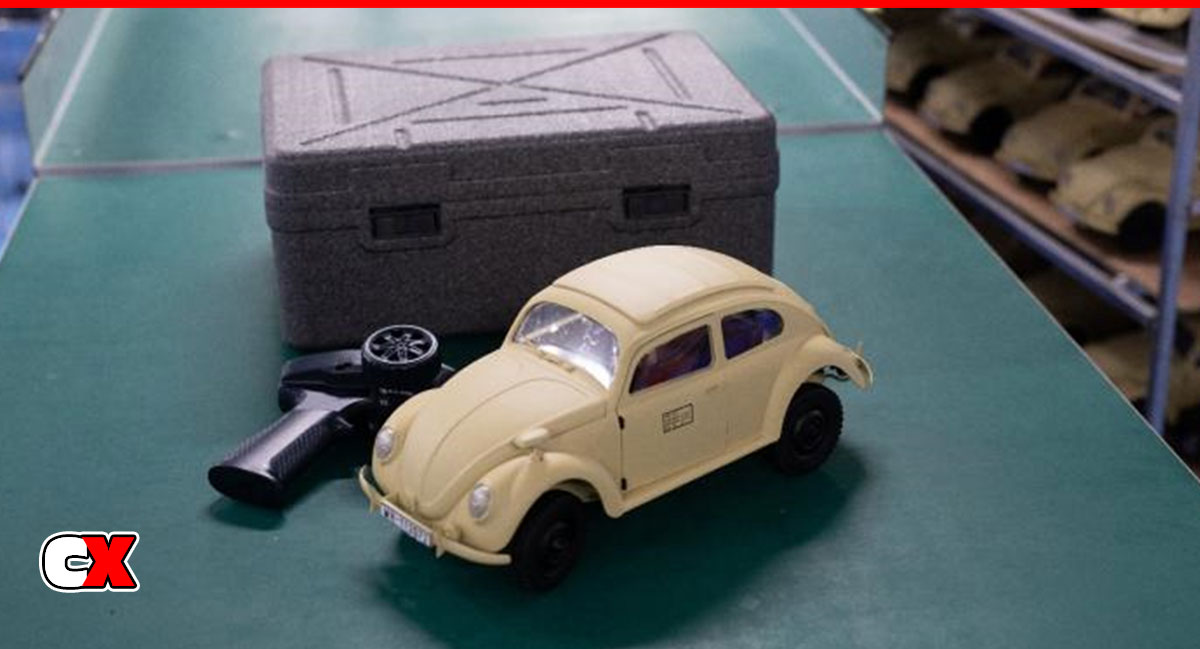

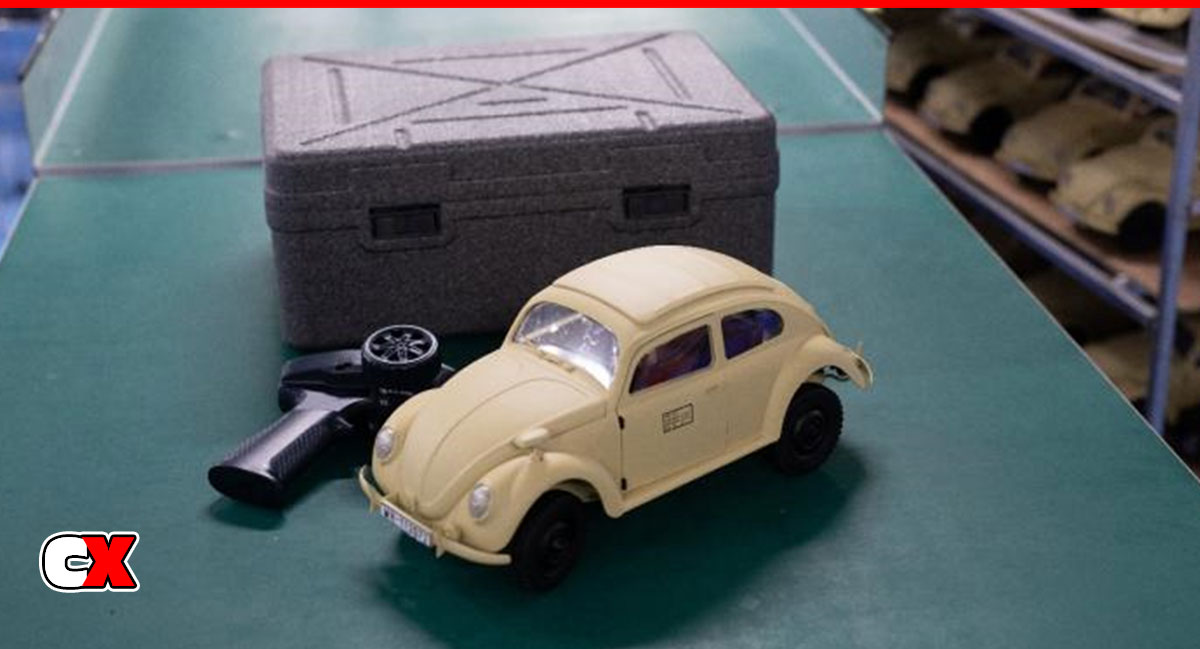

After all of the assembly work completed, the car is connected to the transmitter and given an actual running test!

Completed products are now in the final cleaning stage. The first step is to blow any dust off and to remove particles adsorbed on the shell because of static electricity. This is followed by an alcohol cotton wipe to remove fingerprints that may be left during the assembly process.

The final step is to pass the quality inspection test. Our inspector checks all the details of the vehicle’s appearance and give it a passing stamp. If the product fails, it is recorded in the small book on the right and sent back through the line to the relevant assembly stations for repair.

Here are the freshly produced Beetles just like the one produced in Wolfsburg 80 years ago (except smaller). These are the inspection-approved products waiting for packaging.

Soon, this model will travel by ship, train or plane around the world to different model stores, toy stores, Taobao, Amazon – even to your front door! The appearance, interior detail and mechanical chassis structure and function is modeled right after the original vehicle!

This has been a fun article series about the ROCHobby Type82E Kommandeurwagon. We’re happy that we were able to work with ROCHobby, showing the build process of this cool little 1/12 scale ride. It was an enlightening experience to see how much work goes into something like this!

Make sure you check out our unboxing video of this cool little 1/12 Beetle: Video: ROCHobby Type82E Kommandeurwagen | CompetitionX

Sites to buy:

FMS Model: https://bit.ly/3QHFm5t

Fair RC: https://bit.ly/3KSIJoj

Amazon:

US: https://amzn.to/3G0lx3r

JP: https://amzn.to/3qS2Lao

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.

CompetitionX CompetitionX is the most up-to-date source for RC Car News, Reviews and Videos for Radio Control. We also have the most comprehensive Manual Database on the web.